The hidden side of water softeners

The traditional salt decalcifier is an anti-scale chemical treatment system. The procedure used to remove lime is based on ion exchange, i.e. calcium and magnesium ions are exchanged for sodium ions.

Despite solving the problem of lime in the short term, salt decalcifiers bring new problems: the sodium released is a highly polluting and harmful component, both for the health of people and for the facilities.

Operation of the water softener by ion exchange

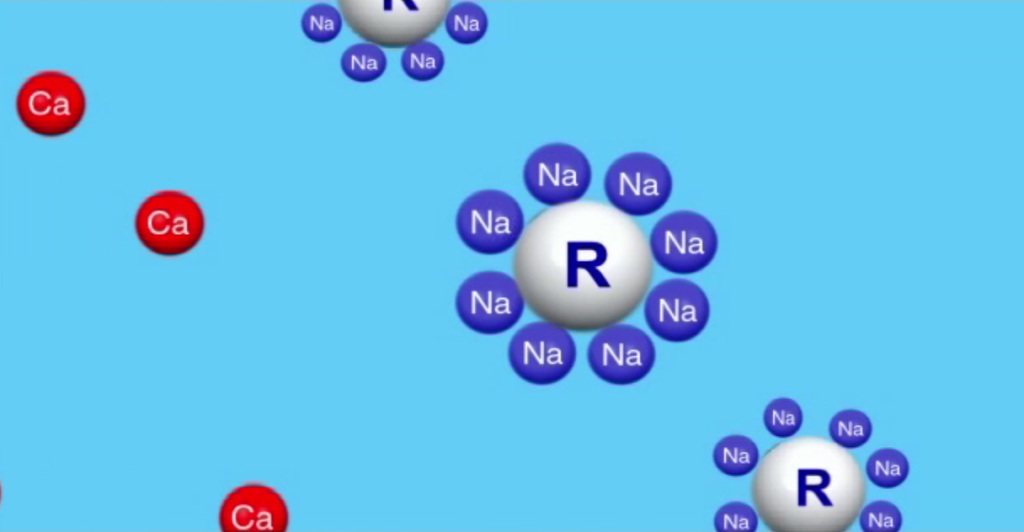

Traditional decalcifiers use a resin to carry out the ion exchange. This resin is a synthetic polymer which in this case is called cationic resin because it is negatively charged. In this way it attracts positive ions such as calcium and magnesium.

The process of a salt decalcifier consists of two phases, a decalcification phase and a regeneration phase.

1- Decalcification phase

The mains water passes through the reservoir containing the resin. The calcium/sodium exchange takes place on contact with this resin loaded with sodium ions. The calcium-free decalcified water then passes through the system and the cold water and hot water circuits.

Calcium in suspension in water and resins charged with sodium ions.

– Water that is neither potable nor fit for human consumption

This process, however, is a major health problem, as water from taps and showers contains high levels of sodium.

The traditional salt decalcifier modifies the chemical characteristics of the water and causes sodium levels to exceed the limits permitted by European and Spanish regulations: 200 mg/litre. Therefore, the water treated by the salt decalcifiers is neither potable nor suitable for human consumption…

The water softener releases sodium in the same proportion as the captured calcium. The harder the water, the more sodium is released in the facility.

– Corrosion in installations and domestic appliances

A decalcified water with a high sodium content favours corrosion, which is a problem for installations and domestic appliances.

In addition, corrosion causes the release of toxic heavy metals that are present in installations. Some, such as iron or zinc, are not harmful in small amounts. However, others such as lead and mercury can cause disease over time by accumulating in living organisms.

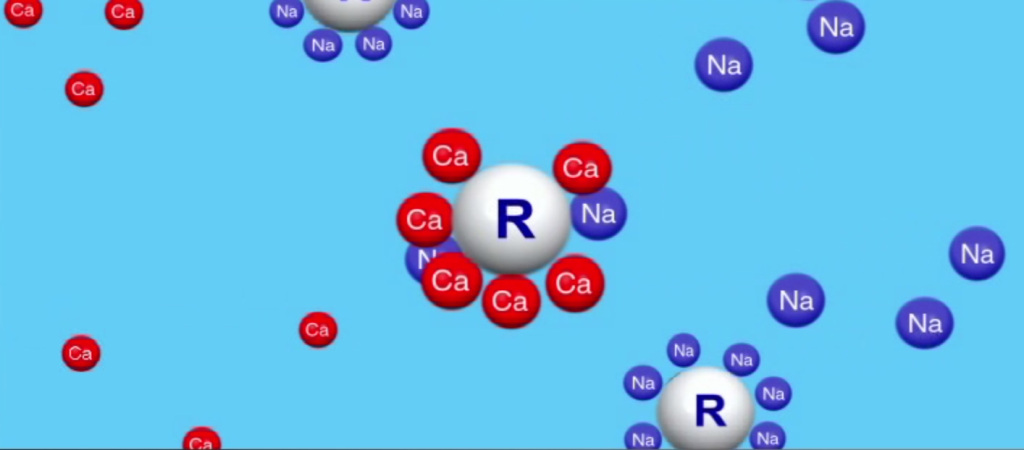

Ion exchange: resins exchange sodium ions for calcium ions.

2- Regeneration phase

This regeneration process is necessary when the resin reaches a saturation point and cannot capture any more calcium ions.

The decalcifier also consists of a tank containing salt dissolved in water. In this cycle, water with a high sodium content is passed through the container containing the resin. In this way there is an exchange between the calcium ions that have adhered to the resin and the sodium ions of the salt, thus regenerating the resin.

– Overconsumption of water

The main problem with regeneration is that it leads to higher water consumption. Salt softeners need periodic regeneration of ion exchange resins. They can reject up to 200 litres of water per regeneration. The frequency of regeneration can vary between 4 and 7 times per month. For this reason, water consumption and water bills increase with the salt decalcifier.

– Pollutant effect

On the other hand, the water with a high sodium content that has been used to regenerate the resin is evacuated through the drain, becoming a great source of pollution. Sodium is a very contaminating component and difficult to eliminate.

Scheme of a traditional salt decalcifier with a tank for the resin and another for the salt.

Types of salt decalcifiers

There are two models of salt decalcifiers:

– Volumetric system: with this system the regeneration of the resin occurs when a certain volume of water passes through the decalcifier.

– Timer system: a chronometric descaler is programmed so that the resin regenerates from time to time. In this way the regeneration will take place independently of the water consumed.

.

Inconveniences of the traditional decalcifier

– Continuos salt supply

The traditional salt decalcifier requires constant maintenance, as salt levels must be checked continuously and sacks of salt must be added regularly. The salt is necessary for the regeneration of the resin.

– Heath risk

Comprehensive maintenance is necessary to reduce bacteriological risks, as there is a danger of bacterial proliferation in aqueous environments and at a certain temperature.

– High maintenance cost

The annual cost of this maintenance is very high, since in addition to the amount of salt used, it is necesarry to take into account the water wasted in each regeneration of the ion exchange resins.

– Water not suitable for irrigation

A high sodium content in irrigation water affects soil permeability and can cause infiltration problems. Excess sodium also causes soil dispersion and disaggregation.

.

Drinking water legislation

The European Union defines the basic quality standards for water intended for human consumption (for drinking, cooking, preparing food or for other domestic uses), either in its original state or treated. Both European Directive 98/83/EC and Royal Decree 140/2003 set the sodium limit at 200 mg/litre for drinking water.

Under hard or very hard water conditions this maximum level is more likely to be exceeded in water intended for human consumption. This is because the sodium released by the resins during the decalcification phase is added to the sodium contained in the water before it is treated.

Royal Decree 140/2003 also makes reference to the complementary treatment of the quality of water for human consumption and establishes that a house must leave at least one point of water intended for food that does not come from the decalcifier.

.

New generation Dropson anti-scale technology

For all the reasons described above, Dropson has designed new generation systems that offer less demanding and highly efficient solutions.

Among the systems on the market, Dropson brand products are distinguished by their innovative concept and outstanding efficiency.

Dropson has developed a proprietary EMI (Electro Magnetic Impact) technology that provides high performance.

Each treatment cell is calibrated at the factory, adapting to a flow curve and a water hardness scale specific to each model.

How does it work?

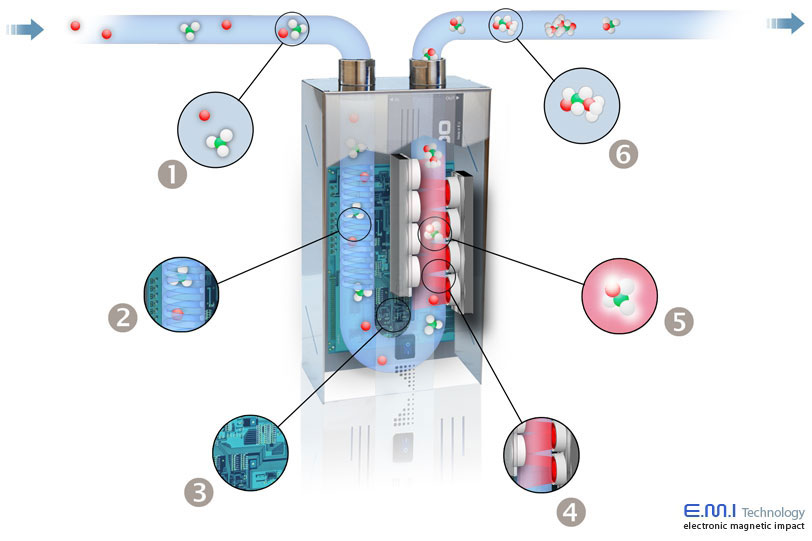

Scheme of operating of a Dropson decalcifier

The laminar flow of your installation is transformed into turbulent flow by the action of the Dropson vortex effect (2).

At the same time, an electronic module (3) controls different multi-zone magnetic field generators (4). These frequency-specific magnetic impacts act directly on the turbulent flow water flow.

The association of the kinetic energy of the vortex with the magnetic impacts generates crystallization (5) between the calcium ions and the carbonate ions responsible for the formation of lime, which are suspended in the water (1).

Microcrystals are created before calcium and bicarbonate enter into the installation. They have a non-embedding structure, so they will pass through the installation without embedding and will be evacuated by taps and drains (6).

Effects of treatment with the Dropson anti-scaling system

The treatment of water with Dropson has two effects:

– Preventive effect: the lime microcrystals created have a homogeneous shape and have a structure that makes them non-fouling. In this way they pass through the installations without being embedded in pipes or electrical appliances.

– Curative effect: the water treated with Dropson has properties that favor the descaling of the lime already existing in the facilities.

At the moment of crystallization the bicarbonate loses its hydrogen atom. This hydrogen will combine with other bicarbonate ions, giving rise to a new molecule: carbonic acid (H2CO3). This acid is capable of progressively dissolving the lime by means of a process of natural hydric erosion.

Benefits of the Dropson electronic water softener

– No maintenance required

The Dropson electronic anti-scaling system requires no maintenance and requires no salt.

– Ecological system

Dropson does not generate any chemical or salt waste, so it does not pollute and is an environmentally friendly system.

– Economic system

The Dropson anti-scaling system guarantees energy savings, as it maintains the optimum conditions for thermal exchange between the primary and secondary circuits, avoiding lime deposits.

In addition it does not need maintenance nor preiodic adjustment.

– Protection of installations

Dropson’s treatment does not use salt, a source of accelerated corrosion of the installations. It allows the good operation of taps, showers and other water outlets, since the mechanisms are free of lime.

Dropson also protects the heating elements of household appliances such as dishwashers and washing machines. It is therefore a guarantee of durability for your installations.

– Water retains its original properties

The Dropson anti-scaling system respects the potability of water and its natural composition. Water treated with Dropson is suitable for human and animal consumption. Dropson has a sanitary certification (ACS) approved by the French Ministry of Health.

– Water suitable for irrigation in gardens

The water treated by the Dropson decalcifier is particularly suitable for watering gardens. It allows a better absorption of the nutrients and a greater development of the plants.

The Dropson electronic water softener ensures homogeneity in irrigation. It avoids incrustations and flow reductions in nozzles and sprinklers.

.