Heat Pump: Complete Guide for Improved Performance

In this article, we explore how to maximize the efficiency of heat pumps, highlighting the revolutionary role of the Dropson anti-scale system. This approach not only enhances the energy performance of heat pumps but also promotes a sustainable and economical solution for scale control. Discover the keys to optimizing your domestic hot water system, ensuring efficient operation and extending the lifespan of your equipment.

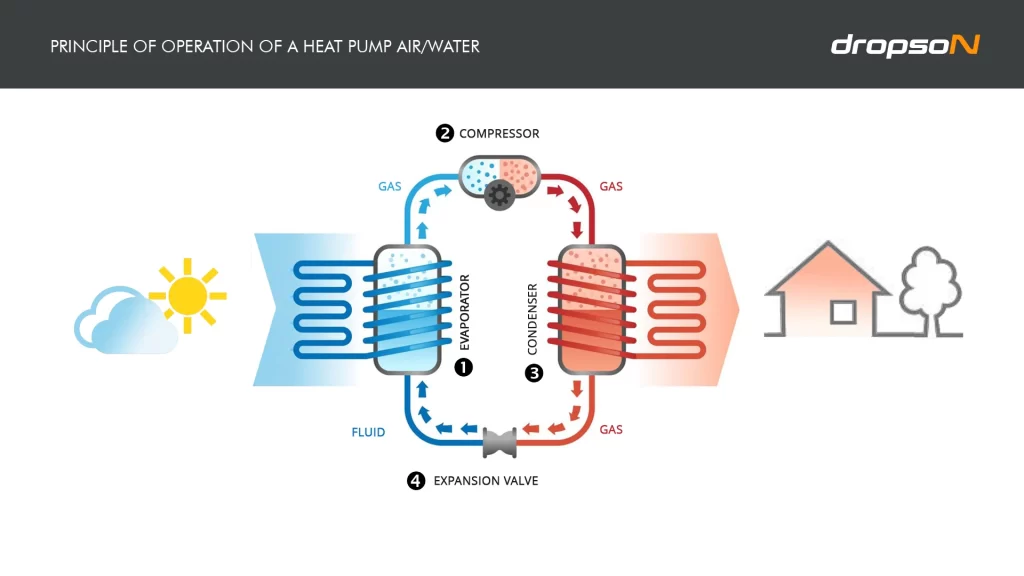

Operating Principle of an Air/Water Heat Pump

- Heat pumps utilize the heat from the outside air, even in low-temperature conditions, to heat or cool our homes.

- The process begins with the absorption of calories (thermal energy) present in the outside air, energy that is inexhaustible due to its solar origin.

- Inside a heat pump circulates a heat-carrying fluid, that is, a fluid capable of transporting heat. This liquid has the particularity of turning into gas at a low temperature, so the heat from the outside ambient air will cause it to go from liquid to gas when it passes through the evaporator.

- Subsequently, the gas is compressed by a compressor powered by an electric motor to increase its temperature, and the obtained thermal energy is transferred to the home’s hot water and heating system.

- Finally, the gas loses heat, condenses back into a liquid state, and the cycle restarts, returning to its starting point.

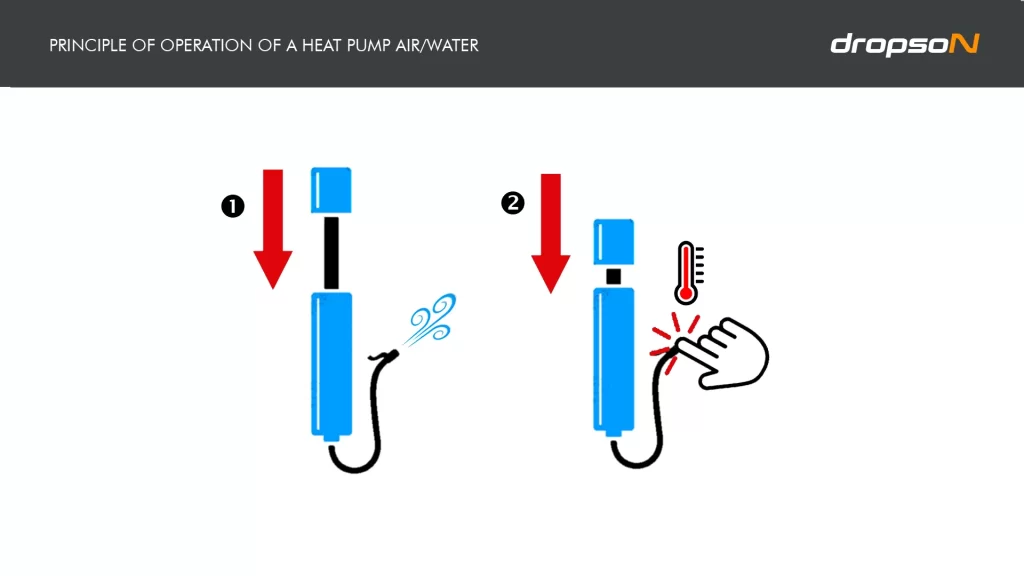

This mechanism is similar to the one generated when compressing air in a bicycle pump: when the end is blocked and the air is compressed, it heats up.

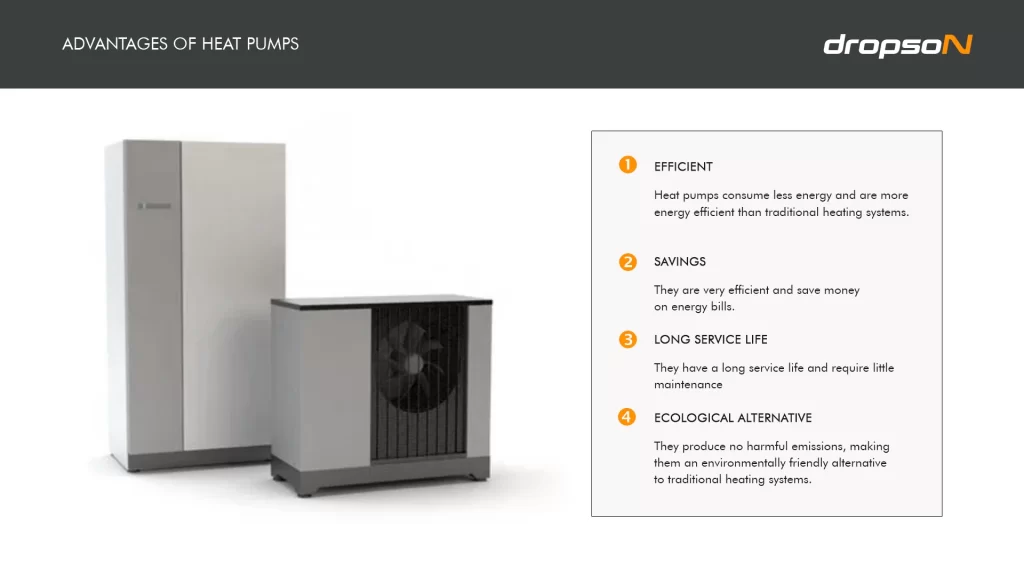

Advantages of Heat Pumps

The advantages of heat pumps over conventional heating systems are numerous and significant.

Efficiency

These systems, by utilizing external ambient heat, consume less energy than traditional methods that generate heat through the combustion of fossil fuels or the direct conversion of electricity into heat. This feature not only reduces energy expenditure but also CO2 emissions, aligning with carbon footprint reduction goals.

Savings

The efficiency of a heat pump is measured through the coefficient of performance (COP), which indicates the ratio between the amount of heating or cooling energy provided and the electric energy consumed. Under optimal conditions, a heat pump can have a COP of 3 to 5, meaning that for every unit of electricity consumed, the system can produce 3 to 5 units of heat. This efficiency translates directly into savings on energy bills for users.

Long Lifespan

They have a relatively long lifespan with proper maintenance, which is comparable or even superior to many traditional heating solutions. The long-term savings in operational costs and the minimal maintenance required more than compensate for the initial investment.

Eco-Friendly Alternative

Another highlight is their flexibility and ability to provide not only heating but also cooling, making them an all-in-one solution for home comfort throughout the year. Additionally, as they do not directly generate harmful emissions at the point of use, heat pumps represent an environmentally friendly option, contributing to less air pollution in residential areas.

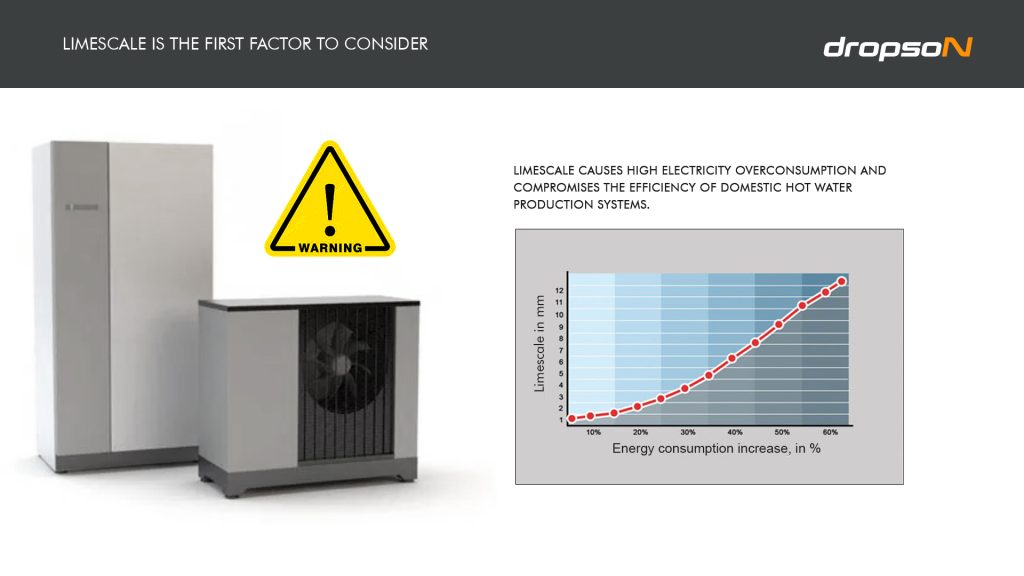

How does scale negatively affect the efficiency of heat pumps?

Scale is a critical factor that negatively impacts the efficiency of heat pumps. Its presence in the heat exchange system leads to overconsumption of electricity, diminishing overall efficiency.

Just 3 mm of scale can increase energy consumption by 30%, significantly raising operational costs. The quality of tap water negatively affects thermal exchange systems. This not only increases the energy bill but also maintenance expenses, as more frequent interventions are required to descale and protect the vital components of the system.

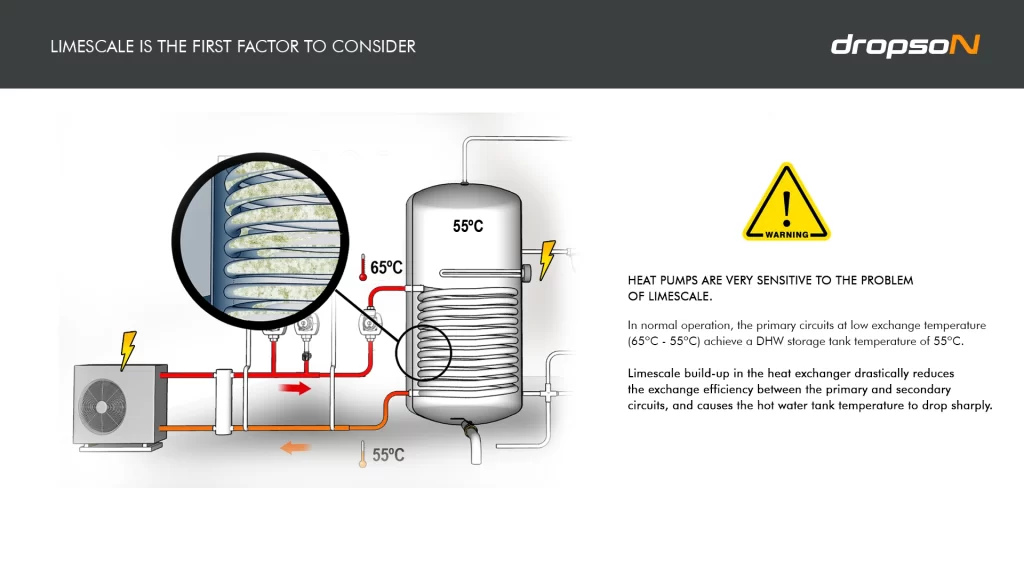

In normal operation, the low-temperature primary exchange circuits (65°C – 55°C) achieve a domestic hot water (DHW) tank temperature of 55°C.

The accumulation of scale in the heat exchanger drastically reduces the efficiency of exchange between the primary and secondary circuits and causes the DHW tank temperature to drop sharply.

Dropson Anti-Scale System as an Eco-Friendly Alternative to Traditional Water Softeners

The Dropson anti-scale systems are an eco-friendly alternative to traditional salt-based water softeners and a guarantee of energy savings.

They prevent the accumulation of scale on heat exchange elements and maintain optimal and sustained performance of the installations. Dropson directly influences energy consumption by ensuring optimal heat exchange conditions between the primary and secondary circuits.

It uses EMI (Electronic Magnetic Impact) technology that acts on calcium and carbonate ions in the water, transforming them into non-incrusting microcrystals that simply flow through the system without adhering to surfaces. This eco-friendly method ensures that heat pumps operate efficiently, without the adverse effects associated with traditional descaling systems.

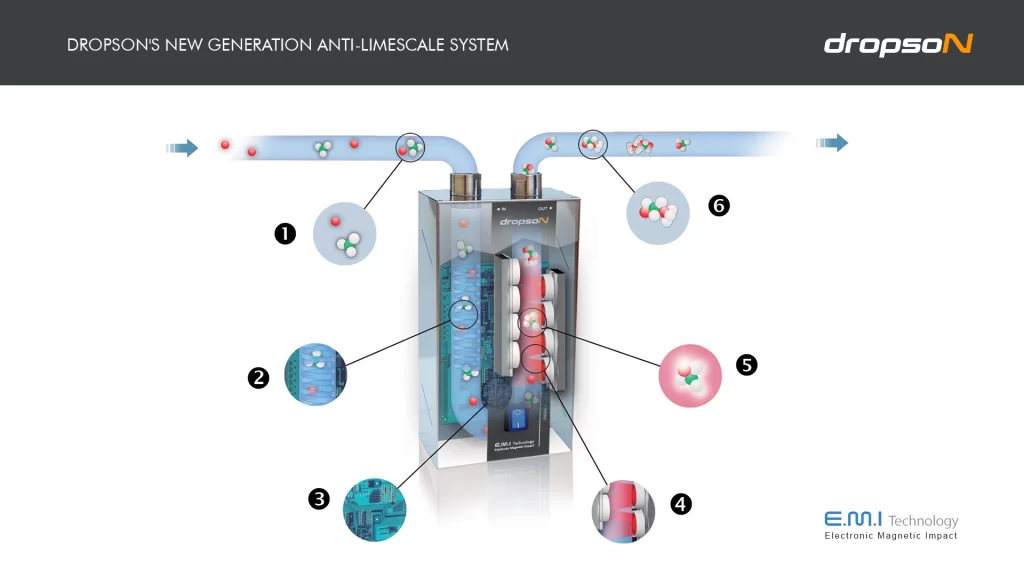

1- WATER INLET

The calcium ions (Ca) and carbonate ions (CO3) responsible for scale formation are suspended in the water.

2- VORTEX EFFECT

The laminar flow of your installation is transformed into turbulent flow thanks to a vortex system.

3- ELECTRONIC MODULE

Controls, through multiple zones, different magnetic impact generators.

4- MAGNETIC IMPACT GENERATORS

The impacts work at specific frequencies and act directly on the turbulent water flow.

5- CRYSTALLIZATION

The association of magnetic impacts and the kinetic energy of the vortex generates crystallization between the calcium ions and the carbon ions suspended in the water.

6- MICROCRYSTALS

The created microcrystals have a non-incrusting structure. They cannot adhere to any support since they are already crystallized. They will pass through your installation without incrusting and will be evacuated through the taps and drains.

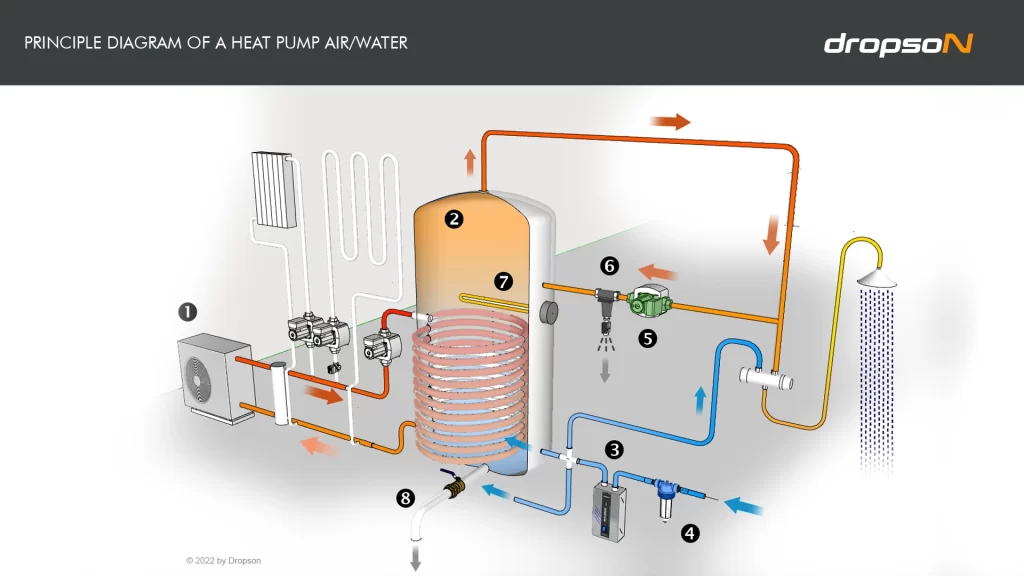

Air/Water Heat Pump Principle Scheme

Here we can see a schematic of an air/water heat pump system.

At (1) the external heat pump, with its primary circuit connected to the DHW tank (2).

Firstly, I would like to highlight the importance of the DHW tank (2).

1- It is very important to correctly calculate the accumulator volume, as if its capacity is too small for the application’s needs, there’s a risk that the hot water content will quickly empty, and the backup resistance (7) will be permanently requested, which will not be very efficient in terms of energy savings.

To calculate it, the Technical Building Code (C.T.E.) establishes the regulatory framework for compliance with quality standards, considering that, in the case of heaters or heat pumps, accumulation is generally done at a lower temperature (55°C) than an electric or gas accumulator (60 or 65°C).

Therefore, a larger accumulation of hot water is necessary.

2- The type of accumulator with a coil heat exchanger must be adapted to work with a low-temperature primary circuit.

At (65°C input – 55°C output), storage tanks with a coil designed to work with boilers are generally designed for a high-temperature primary circuit (80°C-60°C).

If the correct type of accumulator with a coil (for a low-temperature primary circuit) is not selected, the overall efficiency of the installation will be affected, and the use of backup resistance will increase.

3- It is essential to treat the incoming water to protect the primary and secondary heat exchange circuits from scale and sediments, to protect the sanitary elements and equipment of the installation. This can be done with a DROPSON EMI anti-scale system (3) and a sediment filter (4) preferably equipped with a cartridge with a porosity of 50 microns.

4- Tip: If your installation has a domestic hot water return loop (5), you can install a Dropson particle filter with automatic drainage (6) to periodically remove the microcrystals from the system that could not be removed by the water outlets. It is also recommended to periodically empty the water accumulators by operating the lower drainage valve for about a minute (8).

Keys to Energy Savings

Control Hot Water Consumption

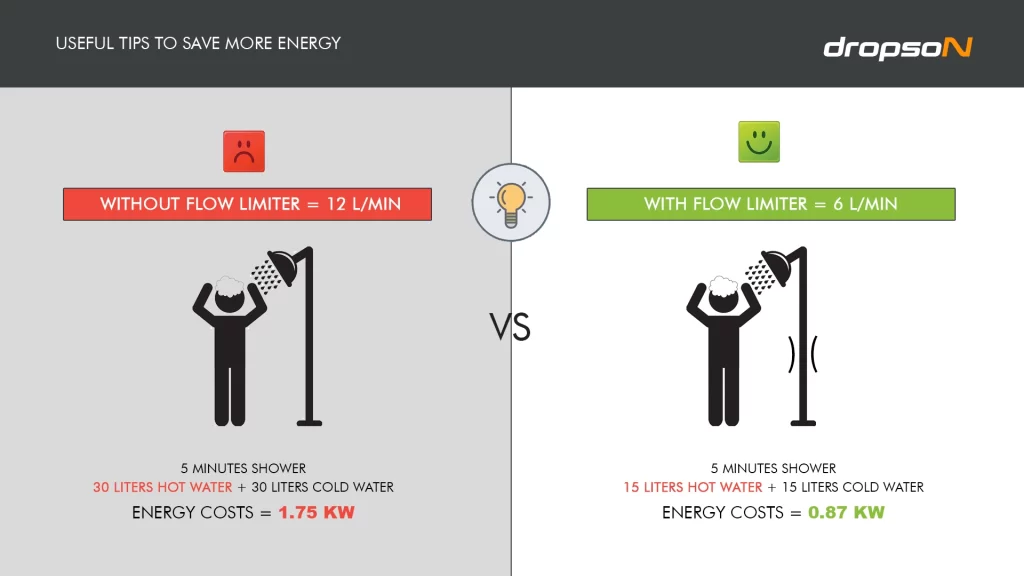

To save energy by controlling hot water consumption, it is crucial to install flow reducers in showers and faucets, which reduces the use of hot water without sacrificing comfort. Using low-flow showers can cut the amount of hot water needed in half, generating significant energy savings. Monitoring and adjusting the storage temperature of hot water to an efficient level also contributes to energy savings, avoiding unnecessary overheating and heat loss.

Conclusion: Energy Savings and Sustainability

To conclude, we review the most important steps to ensure what we call «the energy-saving chain,» for our aerothermal or heat pump installation.

1- Have a heat pump or aerothermal system adapted to the application, and that is correctly calculated according to the building code recommendations and the manufacturer’s recommendations.

2- For your heat pump to function properly and efficiently, it is important to protect the heat exchange circuits and sanitary appliances from scale with the Dropson anti-scale system.

3- To save energy, it is important to reduce or control hot water consumption; this can be done by limiting the flow of sanitary appliances.

Visit Dropson’s website.