Protection of plate heat exchangers with Dropson antiscale systems

Plate heat exchangers are an effective means of providing domestic hot water throughout the world. However, if not properly maintained, they can accumulate sediment, salts and scale deposits that affect the efficiency and safety of installations. The use of an antiscaling system such as Dropson can prevent these problems by keeping the exchanger plates clean. In this article we will look at the benefits of using Dropson to protect plate heat exchangers, how to choose the right one for your installation and the steps to take to maintain safe and efficient operation.

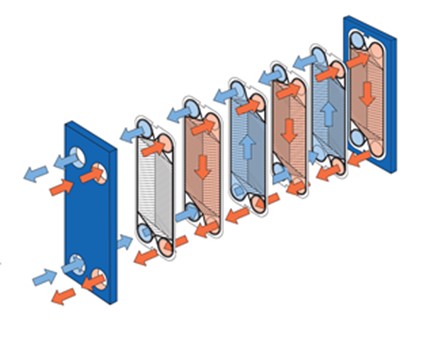

Working principle of a plate heat exchanger

Plate heat exchangers are designed to exchange heat between two separate fluids. This is achieved by the arrangement of metal plates separated from each other. These plates are designed to allow the flow from the primary and secondary circuits to diffuse between them, allowing heat to be transferred from one flow to the other. This heat transfer is achieved without the two fluids mixing together, allowing domestic hot water to be produced safely and efficiently.

What are the advantages of plate heat exchanger technology compared to tube or coil heat exchangers?

Plate heat exchangers offer a number of advantages over tube or coil heat exchangers. These include greater energy efficiency, as plate heat exchangers allow greater heat transfer between the fluids without a large loss of energy. This is because the plates are connected to form a flat surface, which increases the heat transfer area. In addition, plate heat exchangers are more durable than tube or coil heat exchangers, which means they require less maintenance and can last longer. In addition, plate heat exchangers are easier to clean than tube or coil heat exchangers. This makes plate heat exchangers an ideal choice for applications where safe and efficient operation is required.

Why is it important to protect plate heat exchangers?

It is important to protect plate heat exchangers to maintain their proper operation and to ensure that domestic hot water production is safe and efficient. The build-up of sediment, salts and calcium deposits on heat exchanger plates can cause a decrease in efficiency and heat loss, leading to an increase in operating costs. Antiscaling systems help to prevent these problems by keeping the heat exchanger plates clean and reducing the risk of damage to the installation.

Energy challenges

The cost of energy is continually rising and is becoming a challenge to the profitability of companies. Overconsumption, DHW production stoppages and breakdowns all have one factor in common: limescale.

The unknown in the energy equation remains the quality of the mains water. 3 mm of limescale between the heat exchange system and the water leads to a 30% increase in energy consumption. The quality of the mains water negatively affects the heat exchange systems thereby increasing the energy bill.

DROPSON new generation antiscaling system

Dropson antiscaling systems use an innovative technology that makes them a truly environmentally friendly alternative to traditional salt water softeners.

The systems feature advanced electronic antiscaling technology which, together with calculation software, allows to effectively protect the DHW production systems.

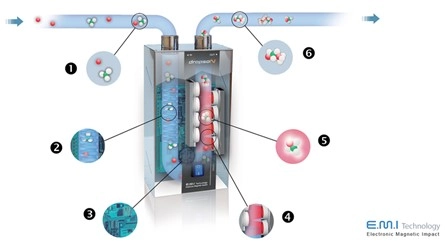

Dropson’s EMI technology

(1) The system water contains calcium and carbonate ions, which are responsible for limescale formation, and these ions are suspended in the water.

(2) Vortex effect. The laminar flow of the system is converted into a turbulent flow by a vortex system.

(3) The electronic module.

Controls the different magnetic impact generators in multi-zones.

(4) The magnetic impacts operate at specific frequencies and act directly on the turbulent water flow.

(5) Crystallisation. The combination of the magnetic impacts and the kinetic energy of the Vortex generates crystallisation between the calcium and carbon ions suspended in the water.

(6) Microcrystals. The microcrystals thereby created have a non-fouling structure, they cannot adhere to any support, because they are already crystallised. They will pass through the installation without becoming encrusted and will be evacuated by taps and pipes.

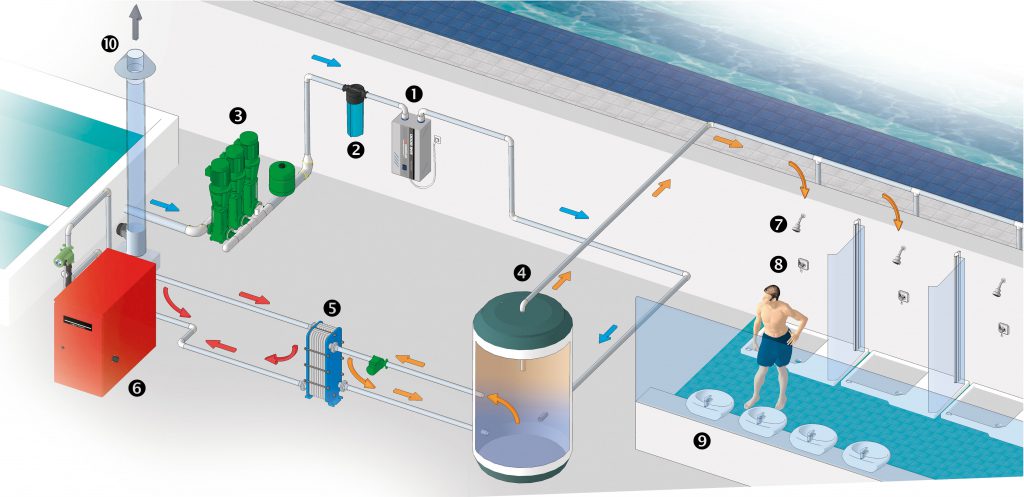

Schematic diagram of installation principle

Dropson is easily installed in the general cold-water inlet, just downstream of the booster set. (1), it is maintenance-free, does not require salt to be added and does not waste water. Its electricity consumption is minimal. It is equivalent to that of a low-energy light bulb and does not generate any load loss in the circuit.

(2) A sediment filter must be installed in the circuit before Dropson. This will prevent the installation from being loaded with silicon or other particles in suspension. These particles can clog certain parts of the installation, promote corrosion or damage the recirculators of the recycling circuits.

(4) Dropson is indicated to fight against the proliferation of legionella, as it prevents the accumulation of limescale both in the installations and in the tanks, thereby reducing the biotope of the latter. It is a guarantee of durability for your installations and accumulators, as it does not use salt like traditional softeners, a source of accelerated corrosion of the installations.

(5) Dropson ensures an optimal and uninterrupted performance of your heat exchangers, preventing

It guarantees long-term energy savings. Avoids dismantling, unexpected maintenance and production stoppages.

(6) Dropson does not act directly on the primary circuit of the boiler, but it has a direct influence on the energy consumption by optimising heat exchange between the primary and secondary circuits.

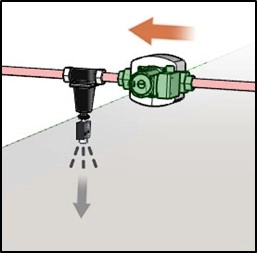

(7) Dropson, by preventing fouling, maintains the calibrated flow rate of the showers, avoids disassembly and untimely maintenance and guarantees the satisfaction of your customers.

(8) The treatment with Dropson ensures the correct functioning of your timed taps. By avoiding limescale incrustation, the mechanisms are not blocked and maintain their original function, saving water and energy. The limescale already accumulated in the installations dissolves progressively.

(9) Dropson guarantees the proper functioning of your taps and aerators.

(10) Dropson avoids over-consumption of energy and thereby reduces C02 or greenhouse gas emissions.

For efficient energy management and a significant reduction in energy costs, Dropson recommends a customised study of your installations, with the objective of integrating technologies to optimise DHW consumption, or to operate boilers at low temperatures.

Useful advice

If your installation has a domestic hot water return circuit, you can install a Dropson particulate filter with automatic drainage to periodically remove from the system the microcrystals that could not be removed by the water outlets.

Another filter can also be installed at the outlet of the secondary circuit pump between the storage tank and the plate heat exchanger to remove the microcrystals before they enter the heat exchanger.

Dropson anti-scale systems are really easy to install

They are efficient, require no maintenance, do not require periodic replacement, do not use chemicals, are durable and environmentally friendly, consume very little energy and respect the potability of the water.

It is the ideal partner to protect all types of renewable energy installations and to attend the energy transition process.

Visit Dropson Website